« Blair's legacy? | Main | Sunday sermon »

May 05, 2007

Iron and Steel

Last week Mausi and about 30 of her colleagues had a day off and went to the Saarland, the smallest of the German federal States, to learn more about iron and steel works. Their destination was 'Saarstahl', a company that produces a variety of different steels, as for example one for the Ariane rockets. Until 1986 they also produced the iron they needed for the steel. The iron works have since been turned into a museum and it has even become a part of the UNESCO world cultural heritage. Mausi and her group were given a guided tour and spent a fascinating two and a half hours around and on top one of the giant blast funrnaces.

One of the blast furnaces, hidden behind the chimney

The blast furnaces were used to continuously produced pig iron which was then transformed into steel in another part of the factory. This kind of labour must have been incredibly hard even in the 20th century. The furnace was stoked with alternate layers of ore and coke. Preheated air was blown into the lower part of the furnace. While the ore was melted and travelled downwards, then preheated air travelled upwards, burnt the coke to carbon onoxide which in turn reduced the iron ores to metallic iron. The whole process is of course much more complex but this very simplified description shall do here. The ore was transported to the top of the furnaced on a sort of conveyor belt construction which can be seen on the left side of the photograph above. Tubs, each filled with one ton of ore,

would travel up that construction.

Two of the reddish brown tubs can just be seen inside the steel construction

Sometimes, the chemical process inside the blast furnace would not go according to plan and residues would form would form a big lump which attached itself to the brickwork inside the furnace. Such a lump which could weigh several hundred kilos was called a 'bear'. And it had to be killed! For this purpose restoking was temporarily stopped so that the filling sank below the point where the bear had attached itself to the wall. Then 3 m of sand were added to offer a minimum of heat protection because several workers had to enter the furnace and locate the exact spot where the bear was hiding!

The manhole through which the workers had to enter the furnace

Temperatures were still around 1000 Centigrade or more and maximum exposure time was 90 seconds for each worker. It is impossible to imagine what they must have gone through inside the furnace. Our guide said he had to do it once 40 years ago and the experience is still giving him nightmares. I can well believe that. Once the bear

was located, holes were drilled into the furnace from outside and the bear was killed with small amounts of TNT. Depending on the size of the bear the number of holes could come up to 70. Afterwards a bigger hole was cut into the furnace to rebuilt the inner brickwork and then the hole was closed again. We saw several of those marks on

the furnace.

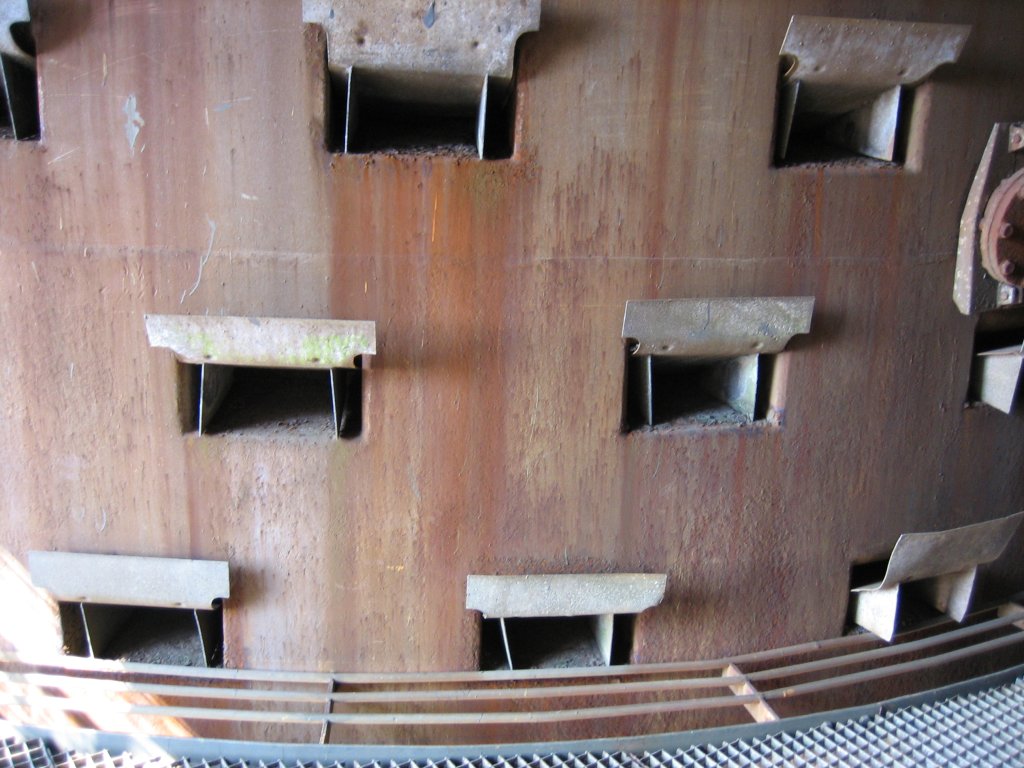

From a certain height downwards the furnace was cooled by a thin film of water running down on its outside. The water would also wash down dust that had settled on the surface. The resulting mud would collect in the pans that can be seen on the photo below.

Pans to collect the mud that is washed down with the water

Each furnace had about 3000 of these pans. They had to be emptied continously by two people working on each shift. The pans were emptied into buckets, the full buckets had to be carried down by hand and the empty buckets up again by hand. Apparently there was no possibility to use a rope or something to lower and lift the buckets. You certainly build up muscles climbing up and down the furnace all day and night.

From the 1960's to 1986 the place must have been humming with activity. At peak times about 17000 people worked there. Each had only access to a very restricted part of the plant. Nothing was dreaded more than industrial spionage. Only now that the iron works have become a cultural heritage are the former workmen allowed to see and visit the rest of their plant.

Nature is alredy trying to take over

Part of the original iron works have already been turned into a museum. But there is still much left to be done. Nature is already trying to take over. But even as it is now it is a fascinating place and if you have the opportunity to visit the 'Völklinger Hütte' you should do so by all means.

Posted by Mausi at May 5, 2007 11:25 AM

Trackback Pings

TrackBack URL for this entry:

http://mt3.mu.nu/mt/mt-tb.cgi/5010